Metal fabrication is no longer the domain of heavy machinery and labor-intensive processes; it has evolved into a dynamic, technology-driven field where innovation is key to performance, efficiency, and sustainability. A convergence of advances in digitalization, automation, and material science is powering this evolution. As industries ranging from automotive and aerospace to construction and healthcare continually seek better, lighter, and more durable solutions, innovative metal fabrication techniques are emerging to meet rising expectations. In the following sections, we’ll delve into the most influential trends shaping modern metal fabrication, providing a comprehensive look at how these advancements are transforming both processes and outcomes for today’s manufacturers.

The drive for progress is fueled by rising demands for increased speed, precision, and adaptability, all while maintaining an unwavering focus on sustainability. Fabricators now benefit from technologies that not only improve quality but also lower costs, strengthen workplace safety, and support complex designs that were once out of reach. These developments address industry challenges, unlock new design freedoms, and enable manufacturers to respond rapidly to shifting marketplace needs. In this article, we examine the groundbreaking innovations that are pushing the boundaries of what is possible in the world of metal fabrication.

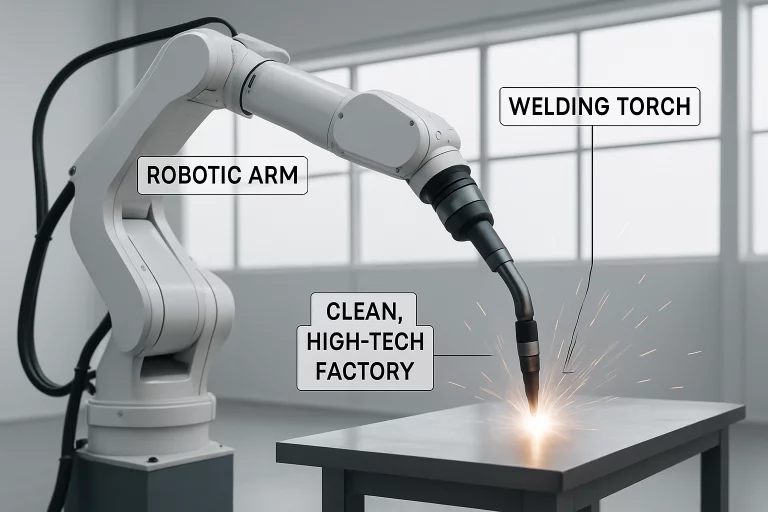

Automation and Robotics

Automation and robotics have become the core of modern metal fabrication, enhancing efficiency, consistency, and machining processes. Advanced robotic arms and work cells are revolutionizing tasks such as welding, cutting, and assembly, delivering precision and accuracy that surpass human capabilities. Automation reduces operational risks, creating safer environments and protecting workers from heat, fumes, and hazardous materials. The integration of machine vision and artificial intelligence allows systems to self-correct and maintain quality in high-speed production scenarios. This hybrid model, which combines skilled humans and machines, has a significant impact on the workforce and productivity, leading to improved job satisfaction and safer work environments.

Additive Manufacturing

Additive manufacturing, also known as metal 3D printing, is a revolutionary method for custom fabrication and prototyping. It builds parts layer by layer from digital designs, using only the exact amount of raw material required. This method conserves resources and supports the production of complex, lightweight components with internal channels and structures. The direct connection between computer-aided design and physical output reduces development timelines, offering greater freedom for creativity. The adoption of metal 3D printing has spread rapidly across various sectors, including aerospace, healthcare, and automotive, reducing lead times, accelerating time-to-market, and fostering innovation.

Smart Manufacturing and IoT

Smart manufacturing is revolutionizing factory floors worldwide, largely thanks to the Industrial Internet of Things (IIoT). This interconnected network of sensors, actuators, and machines forms a responsive digital backbone where data flows seamlessly between physical equipment and decision-makers. Real-time insights enable predictive maintenance, prompt error detection, and continuous process improvement, dramatically reducing downtime and improving consistent output quality. For manufacturers, this means reduced waste, increased resource efficiency, and improved customer outcomes, as orders can be tracked and managed from anywhere.

According to McKinsey’s industry analysis, fully connected factories using IoT have reported equipment efficiency gains of up to 30%, signaling a profound shift toward agile, data-driven operations where insight at every stage is the new standard.

Advanced Materials

The pursuit of performance and reliability has led to significant innovations in materials science, resulting in the development of high-strength alloys, corrosion-resistant metals such as titanium, and lightweight composites. These advancements are crucial for sectors like aerospace and automotive, as they reduce weight while increasing durability. Custom-tailored alloys can be engineered for specific environments, thereby expanding the scope of manufacturing. These advanced materials offer enhanced performance, extended product life, and support eco-friendly manufacturing goals.

Sustainable Practices

Fabricators are increasingly incorporating sustainable practices into their operations, such as utilizing recycled metals, minimizing raw material extraction, and investing in energy-efficient equipment. Lean manufacturing methodologies, closed-loop scrap recycling, and eco-friendly production chemicals help reduce the industry’s carbon footprint. This not only ensures regulatory compliance but also appeals to an eco-conscious market. Meeting international environmental standards boosts corporate image, opens new business opportunities, and ensures long-term viability. Proactive sustainability also makes companies resilient to evolving legislation and climate-related risks.

Customization and On-Demand Production

Advanced manufacturing has become characterized by customization and on-demand delivery. Flexible fabrication methods enable businesses to quickly transition between projects, adapting their output to meet the unique requirements of each customer without inefficiencies. This agility is particularly valuable in industries such as medical technology, military applications, and the production of specialized automotive parts. As product lifecycles shrink and consumer demand for personalization grows, this capability forms the backbone of a responsive manufacturing ecosystem. The seamless integration of rapid prototyping with full-scale production allows companies to iterate, test, and deliver custom solutions in record time, minimizing risk and maximizing profitability.

Digital Twins and Simulation

Digital twins are revolutionizing metal fabrication by creating precise digital models of physical objects. These virtual models enable the simulation and stress-testing of real-world scenarios before materials or labor are utilized. This helps identify weaknesses, refine performance characteristics, and explore alternatives in a digital environment, reducing errors and delays. Digital twins also enable precise maintenance planning, supporting smoother operations throughout the product lifecycle. This digital-first approach supports informed decision-making from concept to final production, saving money and development time.

Collaborative Robots (Cobots)

Collaborative robots (cobots) are a shift from isolated automation to integrated, adaptable systems in factories. Equipped with sensors, safety protocols, and user interfaces, cobots work alongside human operators, assisting with tasks such as lifting, precision placement, and other hands-on activities. They can be quickly reprogrammed and redeployed, supporting small-batch runs or specialized projects with minimal downtime. Cobots also enhance the human workforce by reducing injury rates and allowing people to focus on quality assurance, complex assembly, or creative problem-solving. This blend of robotic efficiency and human judgment creates a more productive, satisfied, and innovative workforce. Metal fabrication companies must remain competitive, resilient, and sustainable in a rapidly changing world.