The Three Pillars: Deconstructing the Oil and Gas Supply Chain

The global economy and our daily lives depend heavily on a steady oil and gas supply. Yet, few understand the immense logistical undertaking required to move these vital resources from remote extraction sites to consumers worldwide. This intricate network, known as oil and gas logistics, is a cornerstone of the energy sector, ensuring crude oil, natural gas, and refined products flow smoothly and safely.

In this extensive guide, we explore the complexities of this critical industry. We will break down the essential components, from upstream exploration to downstream distribution, and examine the primary challenges faced across the supply chain. You will find how advanced technologies like IoT, AI, and blockchain are changing operations, enhancing safety, and driving efficiency.

Furthermore, we will examine how optimized logistics leads to significant cost savings and reduced environmental impact. We will also consider the future trends shaping this dynamic sector, from sustainability initiatives to geopolitical influences.

The oil and gas industry is fundamentally a global supply chain, characterized by distinct phases: upstream, midstream, and downstream. Each phase presents unique logistical demands, requiring specialized solutions and expertise. Understanding these components is crucial to grasping the full scope of oil and gas logistics.

Upstream Logistics: The Foundation of Production

Upstream logistics supports the initial oil and gas production stages, encompassing exploration and extraction. This phase is often characterized by remote, challenging, and sometimes hazardous operations, including deep offshore locations or harsh terrestrial terrains. The logistical demands here are immense, requiring the movement of heavy, specialized equipment, drilling rigs, and a constant flow of materials and personnel.

Key activities include:

- Exploration Support: Transporting geological survey equipment, seismic crews, and initial drilling apparatus to potential sites.

- Drilling Site Supply: Ensuring a continuous supply of drilling fluids, pipes, cement, spare parts, and fuel to active drilling operations.

- Remote & Offshore Operations: Managing complex supply chains for offshore platforms and remote land-based rigs, often relying on specialized vessels, helicopters, and barges.

- Heavy-Lift Transport: Moving oversized and heavy components, such as rig modules or wellheads, requires specialized transport solutions and meticulous planning.

- Personnel Logistics: Coordinating the safe and efficient transport of skilled workers to and from remote sites, including crew changes for offshore platforms.

- Rig Moves: The intricate process of relocating an entire drilling rig from one site to another, demanding precise coordination and specialized heavy transport.

Midstream Logistics: Connecting Production to Processing

Midstream logistics is the crucial link between the production sites (upstream) and the processing facilities (downstream). This phase primarily involves transporting and storing crude oil and natural gas in their raw forms. Given the vast distances and volumes, midstream operations require robust infrastructure and highly efficient transport methods.

Key activities include:

- Crude Oil Transport: Moving crude oil from wellheads to refineries via pipelines, oil tankers (maritime), railcars, and specialized trucks.

- Natural Gas Transport: Transporting natural gas through extensive pipeline networks or converting it to Liquefied Natural Gas (LNG) for shipment via specialized LNG carriers.

- Pipeline Logistics: Managing the construction, maintenance, and operation of vast pipeline networks, including the logistics of materials and equipment for these projects.

- Tankers & Railcars: Utilizing a fleet of specialized ships and railcars for bulk transport, particularly when pipelines are not feasible or for international shipping.

- Storage Facilities: Managing large-scale storage terminals, such as tank farms and underground caverns, to balance supply and demand fluctuations.

- Gathering Systems: Smaller networks of pipelines and facilities that collect raw oil and gas from multiple wells and transport them to larger trunk lines or processing plants.

Downstream Logistics: Delivering to the End-User

Downstream logistics focuses on refining crude oil and natural gas into marketable products and their subsequent distribution to consumers. This phase deals with various finished products, including gasoline, diesel, jet fuel, lubricants, and petrochemicals, each with specific handling and distribution requirements.

Key activities include:

- Refined Product Distribution: Transporting finished petroleum products from refineries to distribution terminals, gas stations, and industrial customers.

- Petrochemical Transport: Handling the specialized logistics for petrochemicals, which often require specific temperature controls, hazardous material protocols, and packaging.

- Last-Mile Delivery: The final leg of delivery to end-users, such as fuel stations, industrial plants, or residential heating oil customers, often involves a dense network of trucks.

- Retail Network Supply: Ensuring that retail outlets, like gas stations, are consistently stocked, managing inventory levels, and optimizing delivery schedules.

- Inventory Management: Sophisticated systems to manage defined product inventory across the distribution network, minimizing stockouts and overstocking.

The sheer scale of this industry is staggering. As of 2024, global oil consumption is all set to reach and surpass the massive value of approximately 103.8 million barrels per day. This enormous demand underscores the critical importance of a seamlessly functioning oil and gas logistics network.

Navigating the Core Challenges in Global Oil and Gas Logistics

The oil and gas logistics sector is arguably one of the most complex and demanding industries globally. It grapples with many challenges impacting efficiency, safety, and profitability. These challenges stem from the nature of the commodity, the environments in which it’s extracted, and the volatile global landscape.

The primary challenges we face include:

- Remote Locations and Harsh Environments: Operations often occur in geographically isolated areas, extreme climates, or deep offshore, making access, infrastructure, and emergency response difficult.

- Geopolitical Instability: Global events, conflicts, and political decisions can swiftly disrupt supply routes, impact pricing, and impose new regulations.

- Market Volatility: Fluctuations in oil and gas prices create uncertainty, making long-term planning and investment in logistics infrastructure challenging.

- Regulatory Complexity: A patchwork of international, national, and local regulations governs the transportation of hazardous materials, environmental protection, and safety standards.

- High Transportation Costs: The specialized equipment, long distances, and unique handling requirements contribute to significant operational expenses.

- Supply Chain Visibility: Maintaining real-time visibility across a vast and often fragmented supply chain is a constant struggle.

Oil, which seems like a basic commodity, accounts for approximately 3% of GDP, highlighting its fundamental role in the global economy and the ripple effect any logistical disruption can cause.

The Impact of Geopolitical Factors and Market Volatility

Geopolitical factors and market volatility are perpetual concerns for oil and gas logistics. Armed conflicts, trade wars, sanctions, and political instability in key producing or transit regions can lead to immediate and severe supply chain disruptions. These events can close shipping lanes, restrict access to specific markets, or necessitate costly rerouting. The result is often increased shipping costs, extended delivery times, and heightened risk.

Market volatility, driven by supply-demand imbalances, economic downturns, or speculative trading, directly impacts logistics planning. Rapid price swings can alter demand patterns, making optimizing inventory levels and transportation schedules difficult. Building resilient supply chains that can adapt to these unpredictable shifts is a continuous endeavor, requiring flexible planning, diversified routes, and strong risk mitigation strategies.

Overcoming Logistical Problems in Remote and Harsh Environments

Operating in remote and harsh environments, such as the Arctic, deserts, or deep-sea, presents unique logistical problems. These locations often lack developed infrastructure, requiring companies to build roads, airstrips, or port facilities. Extreme weather conditions, from blizzards to hurricanes, can halt operations, damage equipment, and endanger personnel.

To overcome these challenges, we often employ:

- Specialized Equipment: Utilizing heavy-duty vehicles, ice-class vessels, and all-terrain equipment designed to withstand extreme conditions.

- Offshore Logistics Solutions: Relying on advanced maritime support vessels, remotely operated vehicles (ROVs), and helicopters for offshore platforms.

- Infrastructure Development: Investing in temporary or permanent infrastructure to support operations, including modular camps, communication networks, and power generation.

- Contingency Planning: Developing robust emergency response plans for accidents, equipment failures, or natural disasters, often involving rapid deployment of resources.

Managing High Costs and Complex Regulations

The high costs associated with oil and gas logistics are driven by the specialized nature of the cargo (often hazardous and oversized), the need for highly trained personnel, and the capital-intensive equipment required. Furthermore, the industry operates under a dense web of regulations to ensure safety and environmental protection.

- Stringent Safety Standards: Adherence to strict international and national safety protocols for handling, storing, and transporting flammable and toxic materials.

- Environmental Compliance: Navigating a complex landscape of environmental regulations to prevent spills, reduce emissions, and minimize ecological impact.

- Hazmat Transport Regulations: Transporting hazardous materials requires specialized handling, route planning, and compliance with restricted zones and designated hazmat routes. Intelligent routing software helps ensure this compliance.

- Customs Clearance and Cross-Border Complexities: Managing diverse customs procedures, tariffs, and trade agreements across multiple countries, especially for international projects.

While essential for safety and environmental stewardship, these regulatory burdens add layers of complexity and cost to logistical operations.

The Technological Revolution in Oil and Gas Logistics

The oil and gas logistics sector is undergoing a profound digital change, leveraging cutting-edge technologies to improve efficiency, safety, and transparency. Integrating IoT, AI, and blockchain is not just optimizing existing processes but fundamentally reshaping how we manage the movement of vital resources.

How IoT and AI are Enhancing Efficiency and Safety

The Internet of Things (IoT) and Artificial Intelligence (AI) are powerful catalysts for oil and gas logistics change.

IoT for Real-Time Monitoring and Tracking: IoT sensors embedded in equipment, vehicles, pipelines, and storage facilities provide real-time data on location, condition, temperature, pressure, and other critical parameters. This continuous stream of information allows for:

- Real-time Asset Tracking: Knowing the exact location and status of every equipment or shipment, from drilling components to refined products.

- Predictive Maintenance: Analyzing sensor data to anticipate equipment failures before they occur, enabling proactive maintenance and minimizing costly downtime.

- Automated Compliance Monitoring: IoT-enabled telematics systems can automate compliance reporting, for instance, by monitoring driving hours to ensure adherence to Hours of Service (HOS) regulations, preventing fatigue-related incidents. Route planning tools can factor in mandatory rest breaks and driving limits.

- Improved Security: Monitoring for unauthorized access or unusual activity in storage facilities and along transport routes.

AI for Optimization and Prediction: AI algorithms process the vast amounts of data collected by IoT devices and historical data to provide actionable insights and automation.

- AI-Powered Route Optimization: AI analyzes factors like traffic, weather, road conditions, and regulatory restrictions to determine the most efficient and safest routes for transport, reducing fuel consumption and delivery times.

- Predictive Analytics: AI models forecast demand, predict potential supply chain disruptions, and optimize inventory levels, leading to better resource allocation and reduced waste.

- Automated Decision-Making: AI can automate routine decisions, such as dispatching vehicles or adjusting inventory, freeing human operators to focus on more complex issues.

IoT and AI create a brilliant and responsive logistics network, significantly improving operational efficiency and bolstering safety protocols across the supply chain.

The Role of Blockchain in Creating Transparent Supply Chains

Blockchain technology, renowned for its secure and immutable ledger system, is emerging as a game-changer for transparency and trust in oil and gas logistics. Its decentralized nature allows for a shared, verifiable record of transactions and events across multiple stakeholders without needing a central authority.

Key applications of blockchain include:

- Secure Transaction Records: Every step in the supply chain, from wellhead to refinery to consumer, can be recorded on a blockchain, creating an unalterable audit trail. This includes ownership transfers, quality checks, and regulatory approvals.

- Improved Traceability: Companies can trace the origin and journey of every barrel of oil or cubic foot of gas, enhancing accountability and verifying ethical sourcing.

- Smart Contracts: Automated, self-executing contracts can be programmed to trigger payments or actions once predefined conditions (e.g., delivery confirmation, quality inspection) are met, streamlining administrative processes.

- Reduced Fraud: TBlockchain’s tamper-proof nature significantly minimizes the risk of fraud, counterfeiting, or data manipulation within the supply chain.

- Improved Stakeholder Trust: By providing a transparent and verifiable record, blockchain fosters greater trust among all participants, from producers and transporters to regulators and customers.

Blockchain doesn’t just improve efficiency; it builds a foundation of trust and verifiable data crucial for an industry as complex and regulated as oil and gas.

The Strategic Imperative of Safety, Compliance, and Sustainability

In the oil and gas logistics sector, safety, regulatory compliance, and environmental stewardship are not merely checkboxes but strategic imperatives underpinning operational success, public trust, and long-term viability. A robust commitment to these areas leads to significant benefits, including cost savings, reduced risks, and a stronger reputation.

Ensuring Safety and Regulatory Compliance

The transportation of highly flammable, corrosive, or toxic materials inherent to oil and gas operations demands an uncompromising focus on safety. Companies must adhere to a complex web of international, national, and local regulations.

Key safety protocols and compliance measures include:

- Rigorous Employee Training: Comprehensive training programs for all personnel involved in logistics, covering hazardous materials handling, emergency procedures, and safety equipment usage.

- Strict Hazmat Handling Procedures: Implementing detailed protocols for the loading, securing, and unloading dangerous goods, including proper labeling and documentation.

- Regular Equipment Inspections and Maintenance: Ensuring all vehicles, pipelines, vessels, and storage facilities are regularly inspected and maintained to prevent failures.

- Emergency Response Planning: Developing and regularly practicing detailed emergency response plans for spills, fires, or accidents, including communication protocols and containment strategies.

- QHSSE (Quality, Health, Safety, Security, Environment) Management Systems: Implementing integrated management systems that consistently adhere to the highest standards across all operations. We have more than 400 Energy and Project Logistics experts in energy hubs and locations worldwide, many of whom are dedicated to upholding these stringent QHSSE standards.

- Route Planning and Risk Assessment: Utilizing advanced software to plan routes that minimize risk, avoid populated areas where possible, and account for potential hazards.

How Optimized Global Oil and Gas Logistics Reduces Costs and Environmental Impact

Optimizing logistics processes goes hand-in-hand with achieving cost savings and reducing environmental impact. By streamlining operations and adopting more innovative strategies, companies can gain a dual benefit:

- Fuel Efficiency: AI-powered route optimization and efficient fleet management significantly reduce fuel consumption, lowering operational costs and decreasing greenhouse gas emissions.

- Reduced Emissions and Carbon Footprint: Beyond fuel efficiency, optimized logistics minimizes empty backhauls, consolidates shipments, and selects the most environmentally friendly transport modes, contributing to a smaller carbon footprint. With improved visibility, carbon tracking and reporting become easier.

- Waste Reduction: Efficient inventory management, facilitated by predictive analytics, reduces overstocking and the associated waste from expired or obsolete materials.

- Minimized Downtime: Proactive maintenance and rapid response capabilities, enabled by IoT and AI, reduce operational downtime, which translates to significant cost savings and prevents potential environmental incidents.

- Sustainable Packaging and Materials: Exploring and implementing eco-friendly packaging and materials for equipment and components, reducing landfill waste.

Adapting to a Sustainable Future

The oil and gas logistics sector is increasingly adapting to sustainability initiatives, driven by regulatory pressures, investor demands, and a growing global awareness of climate change. This adaptation involves a multi-faceted approach:

- Green Logistics Initiatives: Implementing strategies focused on minimizing the environmental impact of logistics activities, including optimizing routes, consolidating shipments, and choosing greener transport options.

- Alternative Fuels and Electric/Hybrid Vehicles: Investing in and transitioning to alternative fuels for transport fleets, such as natural gas, hydrogen, or electric power, particularly for last-mile delivery and port operations.

- Circular Economy Principles: Exploring ways to reuse, repair, and recycle materials and equipment, reducing reliance on virgin resources and minimizing waste.

- ESG (Environmental, Social, and Governance) Reporting: Transparently reporting on environmental performance, social impact, and governance practices to stakeholders, demonstrating commitment to sustainability.

These initiatives are changing the sector, moving it towards a more environmentally responsible and economically viable future.

The Future of the Oil and Gas Logistics Industry

The oil and gas logistics industry is poised for continuous innovation, driven by technological advancements and evolving market demands. The future will see an even deeper integration of digital tools, automation, and sustainable practices, reshaping how resources are moved around the globe.

Key Trends Shaping Global Oil and Gas Logistics

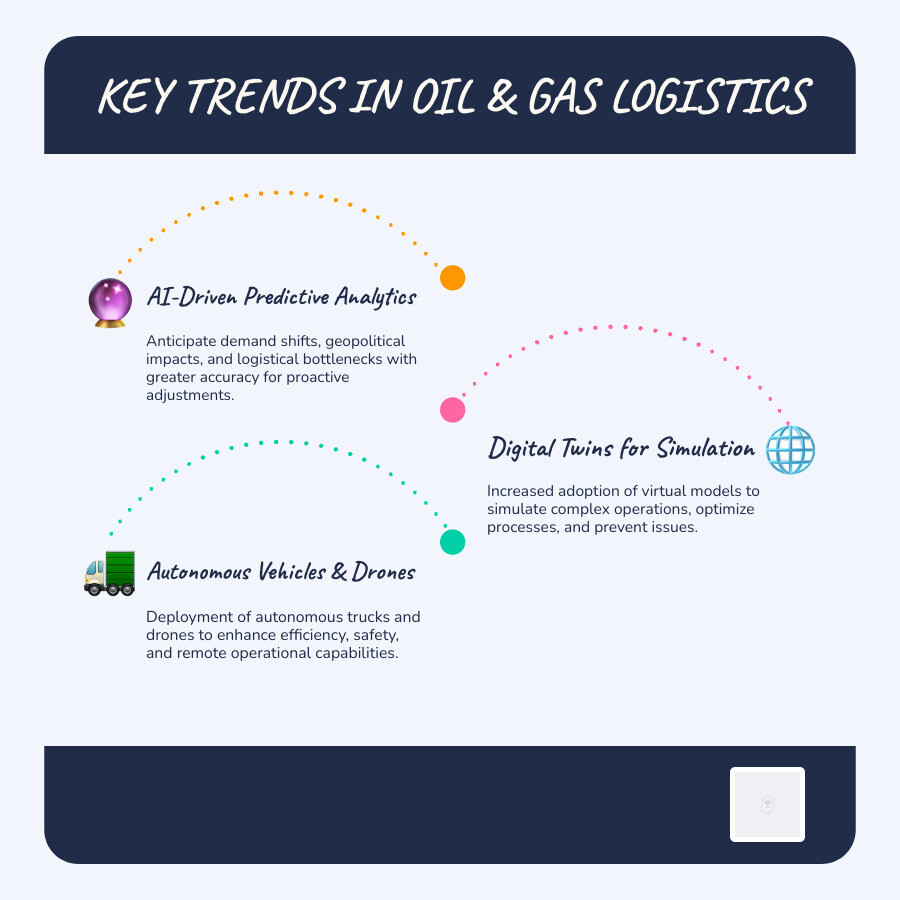

Several key trends are ready to redefine oil and gas logistics:

- AI-Driven Predictive Analytics: Beyond current optimization, AI will enable highly sophisticated predictive models that can anticipate demand fluctuations, geopolitical impacts, and potential logistical bottlenecks with greater accuracy, allowing for proactive adjustments.

- Increased Adoption of Digital Twins for Simulation: Digital twins – virtual replicas of physical systems – will simulate entire supply chain operations, from offshore platforms to refinery distribution networks. This allows for testing scenarios, identifying inefficiencies, and optimizing resource allocation without real-world risk.

- Autonomous Trucks and Drones: While regulatory problems remain, autonomous vehicles, particularly trucks for long-haul routes and drones for inspection and last-mile delivery in remote areas, will become more prevalent, improving safety and efficiency.

- Edge Computing for Faster Data Processing: With the explosion of IoT data, edge computing will process information closer to the source, enabling faster decision-making and real-time responses, which are crucial for critical operations and safety monitoring.

- API Integration for Seamless Ecosystems: Application Programming Interfaces (APIs) will facilitate seamless data exchange between different systems and platforms across the supply chain, creating a more integrated and responsive logistics ecosystem.

The Evolving Role of the Logistics Provider

The evolving landscape requires logistics providers to be more than just transporters; they must act as strategic partners. These integrated service providers, such as Forefront Global Logistics, offer end-to-end supply chain management, from data analysis to navigating complex international regulations. Their role will expand to include:

- Strategic Partnerships: Collaborating closely with oil and gas companies to develop custom, long-term logistics strategies that align with business objectives and sustainability goals.

- Integrated Services: Offering a comprehensive suite of services that spans all three pillars (upstream, midstream, downstream), incorporating advanced technology, and managing all aspects of the supply chain.

- Data Analysis and Consultancy: Providing expertise in leveraging data to identify efficiencies, mitigate risks, and optimize overall supply chain performance.

- Sustainability Leadership: Guiding clients in implementing green logistics practices, reporting on ESG metrics, and transitioning to more sustainable operations.

- Innovation Hubs: Investing in R&D to develop new technologies and solutions that address the unique challenges of the oil and gas sector.

Logistics providers will become indispensable allies, driving innovation and ensuring energy resources’ resilient and responsible flow worldwide.

Frequently Asked Questions about Oil and Gas Logistics

What are the main modes of transport in oil and gas logistics?

The primary modes of transport are pipelines for crude oil and natural gas, tanker ships for international maritime transport of oil and LNG, railcars for bulk overland transport, specialized trucks for refined products and equipment, and cargo planes and helicopters for urgent deliveries to remote or offshore sites.

Why is real-time tracking so crucial in this sector?

Real-time tracking is paramount for several reasons:

- Safety Monitoring: It allows for immediate detection of deviations or incidents, enabling rapid response to prevent accidents or mitigate their impact.

- Security of High-Value Assets: Given oil and gas’s value and strategic importance, real-time tracking provides crucial security against theft or unauthorized access.

- Compliance with Regulations: It helps ensure adherence to strict regulatory requirements for hazardous materials transport and driver hours.

- Proactive Disruption Management: Early warning of delays or issues allows for rerouting or alternative arrangements, minimizing downtime.

- Improved Efficiency: Improved visibility optimizes resource allocation, reduces idle time, and enhances delivery predictability.

What is the difference between upstream and downstream logistics?

Upstream logistics supports the initial phases of the oil and gas industry, focusing on exploration, drilling, and extraction activities. Moving heavy equipment, materials, and personnel to remote well sites, often in challenging environments. Downstream logistics, in contrast, deals with refining crude oil and natural gas into marketable products (like gasoline, diesel, petrochemicals) and their subsequent distribution to end-users and consumers via terminals, pipelines, trucks, and retail networks. Midstream logistics bridges these two, handling the bulk transport and storage of raw oil and gas from production sites to refineries.

Conclusion

The world’s reliance on oil and gas underscores the indispensable role of logistics in this sector. We’ve journeyed through the intricate components of upstream, midstream, and downstream operations, solving the complex challenges of remote locations, geopolitical volatility, and stringent regulations. We’ve also witnessed the transformative power of technology, with IoT, AI, and blockchain revolutionizing efficiency, safety, and transparency.

The strategic imperative of safety, compliance, and sustainability is not just about meeting standards but also about driving innovation, which can lead to significant cost savings and reduced environmental impact. As the industry looks ahead, future trends like digital twins, autonomous vehicles, and advanced analytics promise an even more interconnected and optimized supply chain.

Oil and gas logistics is a dynamic field demanding continuous adaptation and innovation. By embracing technological advancements, prioritizing safety and sustainability, and fostering strategic partnerships, we can ensure the reliable, efficient, and responsible flow of energy that powers our world.